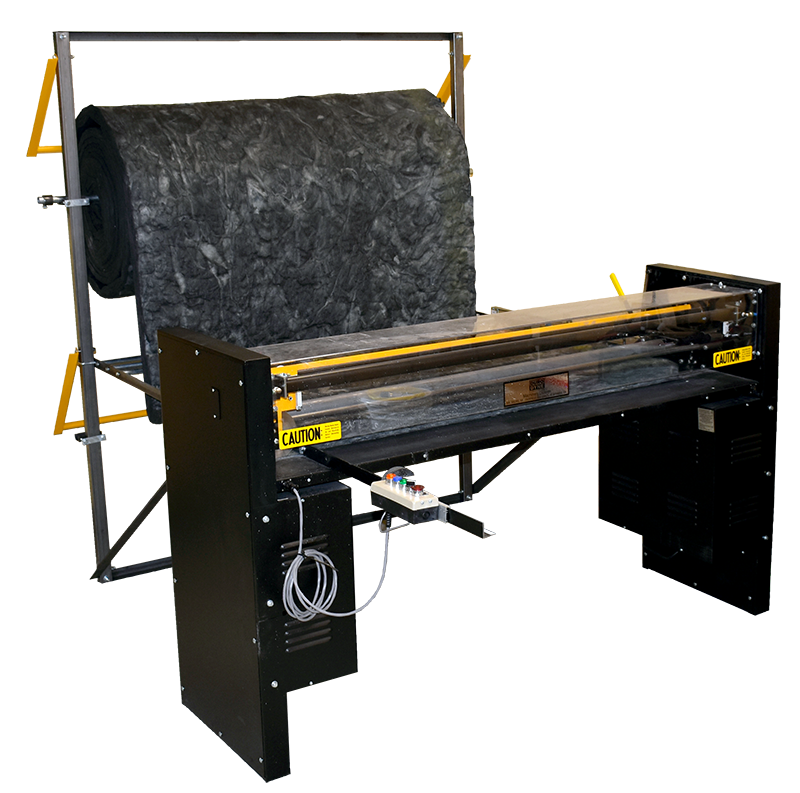

PLSU2 The gear driven slitter and a pulley driven cross cut blade create a powerhouse to tackle all specialty insulations. This new cutting action will allow the PLSU2 to accommodate virtually all insulation types on the market including closed cell products, cotton fiber, Neoprene, Elastomeric Foam & more.

MATERIAL HANDLING - The drive rollers of the PLSU2 also run in reverse for easier material Loading/unloading.

UNIVERSAL WORKFLOW - The portable controls allow for one machine to work for both ‘Left to Right’ and ‘Right to Left’ flows. The PLSU2 can also be manually operated if desired in addition to automatic operation.

CUTTING ASSEMBLY - The PLSU2 comes standard with 1 pul- ley driven cross cut blade for cutting to length and 1 gear driven slitter for cut- ting various widths. Additional slitters can be added (up to 4).

FRAME ASSEMBLY - The insulation rack will hold two rolls of insulation standard as shown. An additional assembly is also available that can accommodate another 2 rolls.

ACCURACY - The PLSU2 is built to maintain a tolerance of + or – 1/4” of length desired as well as slitting accurately to desired widths.

EASE OF ADJUSTMENT - Convenient flip top Plexiglas guards allow easy access for multiple slitter positioning with new safety sensors on Blade enclosures for added protection. The settings for both width and length are made easily and quickly by the mechanic. All machine functions are controlled by 4 push buttons and one toggle switch. Material handling is minimized.

HIGH PRODUCTION - PLSU2 will slit material at the rate of 40 linear feet per minute. Where material is to be cut to length as well, a full roll of insulation can be sized in less than 5 minutes.

RELIABILITY - Duro Dyne’s experience with manual insulation cutters provides the technical know-how for producing a powered machine which will perform to the high standards required. Many PLSU2 insulation cutters are already providing contractors with efficient trouble free production in shops throughout the country.

SAFETY - The PLSU2 is designed with operator safety in mind. Guards and interlock switches minimize the possibility of accidents caused - PLSU2 through operator error.

SERVICE - Duro Dyne, through its regional offices, sales engineers and select distributor organizations, assures you of assistance when required. Our service department technicians are available to help you keep your machine operating in top condition at all times.

FEATURES Durable pulley driven cross cut blade for cutting to length 1 gear driven slitter for cutting various widths. (4 can be added for additional cost) An insulation rack is designed to keep liner square and hold up to 2 rolls standard. An additional assembly is also available that can accommodate another 2 rolls. Micro switch interlocks on all guards for safety. Reliable pneumatic controls Proven 24-volt components for all control circuits.

SPECIFICATIONS Cradle accommodates liner roll up to 60” width, 40” diameter Oil bath reducer with 25 to 1 ratio 1/3 horsepower motor 66” long; 1-1/2” diameter automatic tensioning cable cylinder for cross cut blade. 1 crosscut assembly, 1 slitter assembly Electrical requirements: 110 volt, 15 AMP Air requirements: 80 P.S.I.

OPERATION Place a roll of liner material on the cradle and feed the leading edge of the liner between the pinch roller and the feed roller. To cut multiple pieces of the same dimensions set mode selector switch to “automatic”. Set the PLSU2 for the desired length and width dimensions. To set the width, loosen knob on the slitter assembly and the slide slitter assembly to proper position, retighten the knob. (A metal scale has been installed to ease the width selection.) To set the length, loosen the knob and slide the control unit along the guide to the desired length, retighten the knob. The guide has been equipped with a well calibrated metal scale. Press the run button. The insulation will advance through the rotary knife slitter until it reaches the pre-set length. The liner is then automatically stopped and crosscut to length. As the cut liner is removed from the machine, it automatically restarts. The next piece is slit as it advances through the machine toward the length sensor where it will stop and be cut to length. Removal of the liner starts the next cycle. The machine continues in this mode of operation until the “Stop” button is pressed. For individual pieces of varying lengths, set the mode selector switch to “Manual”. Position the slitter to the desired width and set the length. Press the “Run” button and the material will feed through the slitter into the length sensor and stop. Press the “Cut” button and the material is cut to length and can be removed.

Image 1 of

Image 1 of