- downspout elbow machine, elbow machine, elbow making machine, HVAC elbow machine, chimney elbow

- Industrial Gang Metal Slitter, slitter, ag panel perforator, gang slitter, sheet metal slitter,

- LIBERTY DOUBLE STANDING SEAM ROOF PANEL ROLLFORMING MACHINE SS4E-15

- LIBERTY MANUAL DECOILER D200

- LIBERTY SHEET METAL SLITTER

- LIBERTY SS4E PROFESSIONAL ROOFING MACHINERY

- metal decoiler, uncoiler, de coiler, coil reel, metal coil reel, metal coil decoiler,

- metal roofing equipment

- metal roofing panel equipment

- metal roofing panel machine

- Mobile roof panel roll forming machines, custom design, Double Standing seam, roof panel rollforming

- NEW LIBERTY INDUSTRIAL AND PORTABLE DOWNSPOUT MACHINE

- rollformer

- ROOF PANEL MACHINE

- roof panel machine

- roof panel machines

- roofing machine

- roofing machines

- downspout elbow machine, elbow machine, elbow making machine, HVAC elbow machine, chimney elbow

- Industrial Gang Metal Slitter, slitter, ag panel perforator, gang slitter, sheet metal slitter,

- LIBERTY DOUBLE STANDING SEAM ROOF PANEL ROLLFORMING MACHINE SS4E-15

- LIBERTY MANUAL DECOILER D200

- LIBERTY SHEET METAL SLITTER

- LIBERTY SS4E PROFESSIONAL ROOFING MACHINERY

- metal decoiler, uncoiler, de coiler, coil reel, metal coil reel, metal coil decoiler,

- metal roofing equipment

- metal roofing panel equipment

- metal roofing panel machine

- Mobile roof panel roll forming machines, custom design, Double Standing seam, roof panel rollforming

- NEW LIBERTY INDUSTRIAL AND PORTABLE DOWNSPOUT MACHINE

- rollformer

- ROOF PANEL MACHINE

- roof panel machine

- roof panel machines

- roofing machine

- roofing machines

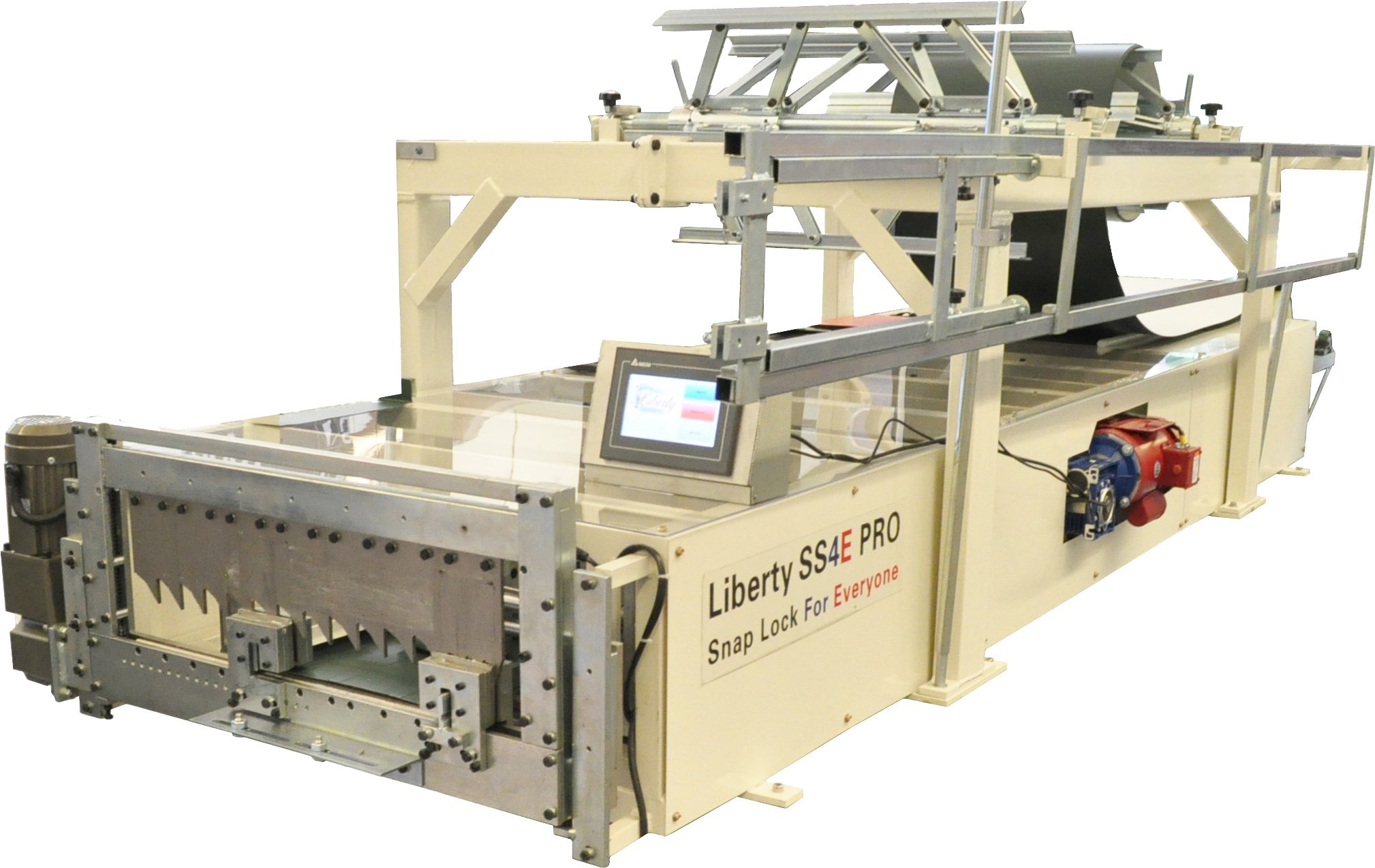

LIBERTY SS4E PROFESSIONAL ROOFING MACHINERY

This advanced Liberty's SS4E Pro machine comes with the most popular snap lock panel in the USA! The 1.75” snap lock! It features our exit end adjustable shear, panels from 12 - 24” wide, 1.5 hp motor, and optional overhead reed rack, and optional expandable arbor reels.

Machine can be mounted on your or a new trailer.

Features:

6 Urethane drive rollers

Free-floating forming rollers mounted

Two sets of bead rollers included

Easy adjustable width of panel from 12” - 24”

Includes clip relief rollers

Easy change to different various profiles (coming soon)

Manual Exit end shear

Material width 18.5” to 30.5”

Limit switch for length control

Liberty wireless control For/Rev Start/Stop

Optional:

Dual overhead reel rack

Expandable arbor reels

Single expandable arbor reel stand

Heavy duty 18 oz Tarpulin cover

Automatic shear

- downspout elbow machine, elbow machine, elbow making machine, HVAC elbow machine, chimney elbow

- Industrial Gang Metal Slitter, slitter, ag panel perforator, gang slitter, sheet metal slitter,

- LIBERTY DOUBLE STANDING SEAM ROOF PANEL ROLLFORMING MACHINE SS4E-15

- LIBERTY MANUAL DECOILER D200

- LIBERTY SHEET METAL SLITTER

- LIBERTY SS4E PROFESSIONAL ROOFING MACHINERY

- metal decoiler, uncoiler, de coiler, coil reel, metal coil reel, metal coil decoiler,

- metal roofing equipment

- metal roofing panel equipment

- metal roofing panel machine

- Mobile roof panel roll forming machines, custom design, Double Standing seam, roof panel rollforming

- NEW LIBERTY INDUSTRIAL AND PORTABLE DOWNSPOUT MACHINE

- rollformer

- ROOF PANEL MACHINE

- roof panel machine

- roof panel machines

- roofing machine

- roofing machines

LIBERTY INDUSTRIAL AND PORTABLE DOWNSPOUT MACHINE

Commercial and Portable Downspout & Elbow Machines

Pipe Size: 2”x 3”; 3” x 3”; 3”x 4”

3” Round

4” Round

CUSTOM

(Each machine does one size and configuration)

Speed:

Standard 30 ft./min.

Optional 45 or 60 ft./min. (aluminum)

Material:

Aluminum .019 - .024 in.

Steel 29 - 26 ga.

Copper 16 oz.

Warranty: 1 year limited parts warranty

Spools: One 15” I.D. spool included

Electrical:

110 volt or 220 volt

ON/OFF switch

Forward/Reverse switch

Entrance JOG button

Models:

Portable or stationary

Semi-automated: length control with limit switch

Round or rectangular models

Drive System: Urethane top and bottom drive rollers

for smooth even, non-twisting drive

Frame: 1” x 5” Aluminum side blocks

Cutoff Mechanism: Hand operated Quadra-shear with built-in crimper or Cutoffsaw (Round models)

Optional automated pneumatic activation

Affordable Industrial Downspout machine.

Pipe Size: 5.25” x 3.5” (133mm x 90mm)

Speed:

25- 33 feet per minute

8 - 10 meters per minute

Material: .015” - .024” (0.4 - 0.6mm)

Shear: Post forming shear, Simens PLC Automatic Controller,

Decoiler: One decoiler with.spool included

Material Width: 17.75” wide coil (452mm)

Dimensions of Line: 55! x 4! x 4.5! high

Included in line:

Decoiler

Guiding Mechanism

Roll Former

Hydraulic shear

PLC Controller

Runout Table

- downspout elbow machine, elbow machine, elbow making machine, HVAC elbow machine, chimney elbow

- Industrial Gang Metal Slitter, slitter, ag panel perforator, gang slitter, sheet metal slitter,

- LIBERTY DOUBLE STANDING SEAM ROOF PANEL ROLLFORMING MACHINE SS4E-15

- LIBERTY MANUAL DECOILER D200

- LIBERTY SHEET METAL SLITTER

- LIBERTY SS4E PROFESSIONAL ROOFING MACHINERY

- metal decoiler, uncoiler, de coiler, coil reel, metal coil reel, metal coil decoiler,

- metal roofing equipment

- metal roofing panel equipment

- metal roofing panel machine

- Mobile roof panel roll forming machines, custom design, Double Standing seam, roof panel rollforming

- NEW LIBERTY INDUSTRIAL AND PORTABLE DOWNSPOUT MACHINE

- rollformer

- ROOF PANEL MACHINE

- roof panel machine

- roof panel machines

- roofing machine

- roofing machines

LIBERTY INDUSTRIAL AUTOMATIC ELBOW MACHINE

Industrial automatic elbow machine designed to produce square and round downspout and HVAC elbows with seamed and welded ducts.

Standard machine size range: rectangle 2x3 to 6x6, round 3" to 8"

Materials: machine operates with pipes made of aluminum, copper, galvanized steel, stainless steel, PPGI.

Final product widely used in downspout, chimney, exhaust and HVAC systems.

Productive capacity depends on size of the pipe and varies in range of 2 to 7 pc per minute.

Advantages:

Easy operation and high performance

Wide operational diameter range 3" - 24" (custom design)

Round and Square dies available

Reasonable price

Main parts:

1. Control Panel

2. Set of dies

3. Angle adjustment (to set required quantity of the crimps).

4. Main motor reducer.

5. Rotary attachment on the side for the round ducts / edge crimping tool for square ducts.

- downspout elbow machine, elbow machine, elbow making machine, HVAC elbow machine, chimney elbow

- Industrial Gang Metal Slitter, slitter, ag panel perforator, gang slitter, sheet metal slitter,

- LIBERTY DOUBLE STANDING SEAM ROOF PANEL ROLLFORMING MACHINE SS4E-15

- LIBERTY MANUAL DECOILER D200

- LIBERTY SHEET METAL SLITTER

- LIBERTY SS4E PROFESSIONAL ROOFING MACHINERY

- metal decoiler, uncoiler, de coiler, coil reel, metal coil reel, metal coil decoiler,

- metal roofing equipment

- metal roofing panel equipment

- metal roofing panel machine

- Mobile roof panel roll forming machines, custom design, Double Standing seam, roof panel rollforming

- NEW LIBERTY INDUSTRIAL AND PORTABLE DOWNSPOUT MACHINE

- rollformer

- ROOF PANEL MACHINE

- roof panel machine

- roof panel machines

- roofing machine

- roofing machines

LIBERTY MANUAL DECOILER D200

Max coil: weight 2000lbs, width 27", ID 18"

Manual Decoiler D200 made to hold a coil of material and spin it to unwind sheet materials from the coil.

Maximum weight of the coil 2000 lbs.

Maximum coil width up to 27 inches.

Decoiler can be used to uncoil metal, plastic, paper and other materials.

Self Centering coil holder is easy to install and fix inside of the metal coil.

Optional modification:

Customization of the ID - OD range;

Installation of the motor, gear box, belt drive and automatic start/stop function with limit switch.

Operation way:

To install the coil with material on the decoiler you must do as follow:

1. Use hand wrench to shrink the reel few inches less than your coil inside diameter ID

2. Set the coil on the reel

3. Expand self centering coil reel with a hand wrench, to fix coil on the reel;

4. Set limiters on the reel paws

5. Adjust brake

Once you pull out age of the material from the coil - coil starts spinning. For convenient operation and safety decoiler equipped with a friction brake, expanding wrench, and limiters for the reel paws.

Safety requirements: maximum weight for the full width coil is 1500lb.

Technical parameters

Range of the Inside coil diameter

13" - 18"

Maximum coil weight 2000 lbs

Maximum coil width 26.5"

Size, LхWхH* 48x40x54 inches

Weight* 500 lbs

- downspout elbow machine, elbow machine, elbow making machine, HVAC elbow machine, chimney elbow

- Industrial Gang Metal Slitter, slitter, ag panel perforator, gang slitter, sheet metal slitter,

- LIBERTY DOUBLE STANDING SEAM ROOF PANEL ROLLFORMING MACHINE SS4E-15

- LIBERTY MANUAL DECOILER D200

- LIBERTY SHEET METAL SLITTER

- LIBERTY SS4E PROFESSIONAL ROOFING MACHINERY

- metal decoiler, uncoiler, de coiler, coil reel, metal coil reel, metal coil decoiler,

- metal roofing equipment

- metal roofing panel equipment

- metal roofing panel machine

- Mobile roof panel roll forming machines, custom design, Double Standing seam, roof panel rollforming

- NEW LIBERTY INDUSTRIAL AND PORTABLE DOWNSPOUT MACHINE

- rollformer

- ROOF PANEL MACHINE

- roof panel machine

- roof panel machines

- roofing machine

- roofing machines

LIBERTY SHEET METAL SLITTER

Industrial 55" wide sheet metal slitter.

Goes with set of five pairs of slitting blades.

Shaft diameter 3.35", both top and bottom shafts have bearing support for heavy gauge metal and perforation stability.

Capacity - 16-30 gauge (depends on quantity of cuts)

Operational speed 150 f/m with default AC Motor 3Hp 110v Single ph. 20 amps.

Three or single phase 220v motors and operational speed are optional.

- downspout elbow machine, elbow machine, elbow making machine, HVAC elbow machine, chimney elbow

- Industrial Gang Metal Slitter, slitter, ag panel perforator, gang slitter, sheet metal slitter,

- LIBERTY DOUBLE STANDING SEAM ROOF PANEL ROLLFORMING MACHINE SS4E-15

- LIBERTY MANUAL DECOILER D200

- LIBERTY SHEET METAL SLITTER

- LIBERTY SS4E PROFESSIONAL ROOFING MACHINERY

- metal decoiler, uncoiler, de coiler, coil reel, metal coil reel, metal coil decoiler,

- metal roofing equipment

- metal roofing panel equipment

- metal roofing panel machine

- Mobile roof panel roll forming machines, custom design, Double Standing seam, roof panel rollforming

- NEW LIBERTY INDUSTRIAL AND PORTABLE DOWNSPOUT MACHINE

- rollformer

- ROOF PANEL MACHINE

- roof panel machine

- roof panel machines

- roofing machine

- roofing machines

DOUBLE STANDING SEAM ROOF PANEL ROLLFORMING MACHINE SS4E-15

SPECIFICATIONS

Length: 5' 4" (1.6m)

Width: 3' 5" (1.1m)

Height: 1' 9" (0.5m)

Weight 1000 lbs. (455 kg)

Speed: 30 ft/min (9m/min) Approx.

Drive: Polyurethane and lower steel forming Rollers

Shear: Manually Powered, Entrance end slitter

Coil Width: 15” to 28" (380mm to 711mm)

Materials Formed

Steel 30 gauge to 24 gauge (.3mm to .6mm)

(painted, galvanized, aluminized)

Aluminum .019" to .032" (.5mm to 08mm)

Copper 16 oz. to 20 oz. 3/4 Hard

(.5mm to .7mm)

STANDARD FEATURES

Polyurethane and Bottom Forming Drive Rollers

Hard Chrome Steel Forming Roller System

Easy to operate Entrance End Manual slitter cutoff

Portable Dongle for Ease of Operation

Width Adjusted with simple crank

Wireless Remote Control

Length Control with Limit Switch

Clip Relief Roller Set included

Double Bead Roller Set

1.5 HP Electric Motor

Welded Tubular Steel Frame

One Year Limited Parts Warranty